WHAT WE DO

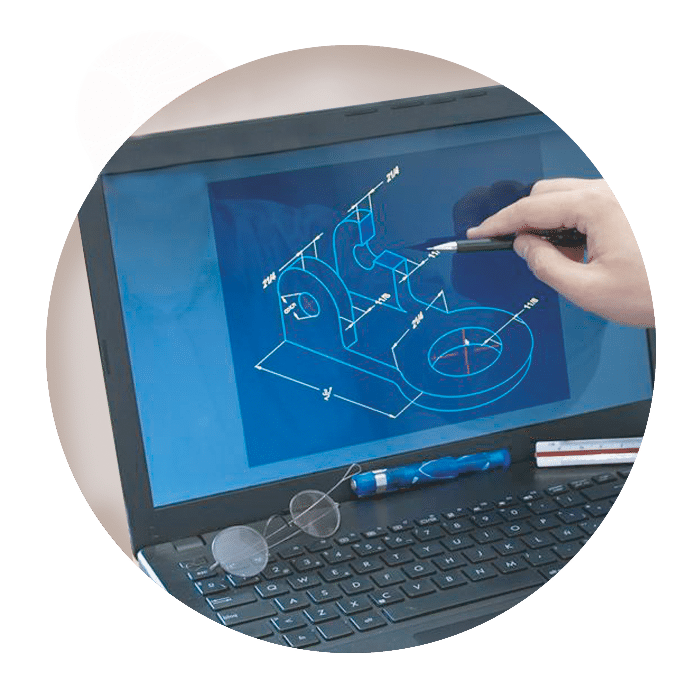

DESIGN

Thanks to our expertise and experience in industrial design, we develop customized solutions to meet the needs of our clients:

3D CAD modeling: we conduct feasibility studies and provide support in modeling using the most advanced software. We create parametric models of complex elements and perform file conversion from ‘3D to 2D’

Topological optimization and F.E.M. simulation: we manufacture reliable and durable products, taking into account the forces and constraints to which the element will be subjected and the required performances. The models are optimized in order to eliminate the unnecessary percentage of material to maintain functional and aesthetic requirements, designing geometries that improve the physical and mechanical characteristics of the products, with important advantages in terms of weight reduction, the number of components and assembly times.

Reverse engineering: we replicate pieces of all shapes and we 3D print them. It is thus possible to reproduce pieces no longer available on the market (for example, out of production objects) or to replace metal and plastic components obtained with traditional technologies.

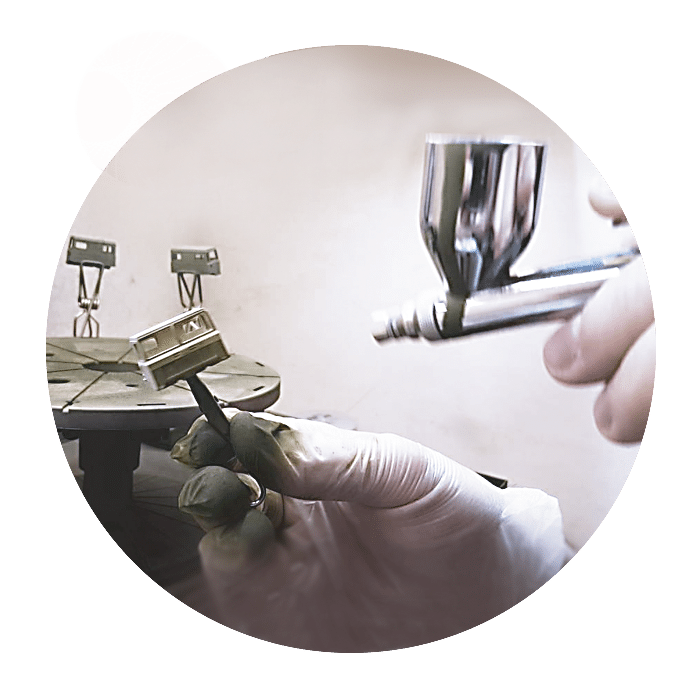

POST PRODUCTION

A large post-production area is dedicated to surface finishing and assembly services. Depending on the customer’s needs, the printed elements will be subjected to surface finishing processes: sandblasting, painting and coating with composite fibers.

In case of large-size pieces request we can use special gluing and dedicated geometries to assembly the different parts to manufacture the desired products.

Three-dimensional experience: Welcome to the world of Fidema 3D Printing!

ABOUT

We are a cutting-edge division that combines design and 3D printing, offering our customers innovative solutions for the modern world. 3D printing is a revolution that has upset many sectors, and Fidema 3D is the key to unlocking the potential of this technology.

Thanks to our engineering expertise and the use of the most advanced technologies, we can create functional prototypes, production tools, conceptual models and even mass production, starting from an idea and shaping it according to the needs of our customers.

Our versatility is our strong point: our high-productivity machines allow us to test new elements quickly, create custom series productions, reproduce existing components and re-engineer solutions.

The sectors in which we operate are vast and diversified: from industrial to medical, from automotive to naval, from aerospace to sports, from food to consumer. Our 3D printing can meet every need, pushing the limits of innovation.

If you are looking for tailor-made solutions, versatility and reliability, Fidema 3D Printing is the ideal partner to explore new production dimensions and give shape to your most ambitious ideas. Join us in this three-dimensional adventure, where technology meets excellence to create the future today.